Green hydrogen buds sprout

Production race picks up speed

James Mnyupe, Namibia's green hydrogen commissioner, emphasises collective efforts for success.

The race to production is on, with the initial stages of construction gaining momentum in pioneering 'green' hydrogen production projects at locations like Walvis Bay and isolated ones like the Daures Green Hydrogen Village, situated more than 50 km from the nearest human habitation. The private sector and academia are gearing up for government's national mega-project, which aims to completely reshape Lüderitz, industrialise the desert, and establish an imposing infrastructure that will dominate the landscape. Green hydrogen production involves utilising renewable electricity to split water molecules into two components: hydrogen and oxygen.

Dr Zivayi Chiguvare of the Namibia Green Hydrogen Institute at the University of Namibia elaborated on the process. Water desalination produces brine, electrolysis yields oxygen and hydrogen, air separation provides nitrogen and oxygen-rich air, and ammonia synthesis involves combining hydrogen and nitrogen to create and store ammonia. These outputs find applications in refrigeration, power generation, cleaning chemical production, fertiliser production, feedstock and agricultural chemicals, fuel cell systems, ammonia engines, and general energy production.

Invest in green hydrogen dreams

James Mnyupe, the green hydrogen commissioner and economic advisor to the president, announced the establishment of a family trust on his birthday earlier this month. The trust is dedicated to funding the studies of two students, specifically aimed at advancing the Namibian green hydrogen industry. Mnyupe aims to set an example for the government to allocate a specific budget towards realising the Namibian 'green' hydrogen dream. "When do we start investing in our dreams?" he noted.

At the recent Namibia Green Hydrogen Masterclass 2023, organised by the Namibia Investment Promotion and Development Board (NIPDB), he emphasised that Namibia must redefine 'hi-tech' to mean 'hy-tech,' with a 'hy-economy' delivering 'hy-fuels.' He stressed the importance of ensuring that no one is left behind in this vision.

“Our desert is a blessing,” he said, which will allow Namibia to produce the lowest-cost clean hydrogen from solar and wind energy. In charge of the development of three massive green hydrogen valleys, – one on the southern coast, one around the central harbour, and eventually a third at the envisaged Angra Fria harbour to be built along the northern coastline – Mnyupe emphasised the importance of “teaming up to meet the demands" of the task.

“Help yourself and help the person next to you, because together is how we will get there,” he said. This month, the Green Hydrogen Namibia Programme hired its first two employees, bringing its workforce, including the commissioner, to three.

Committed partnership

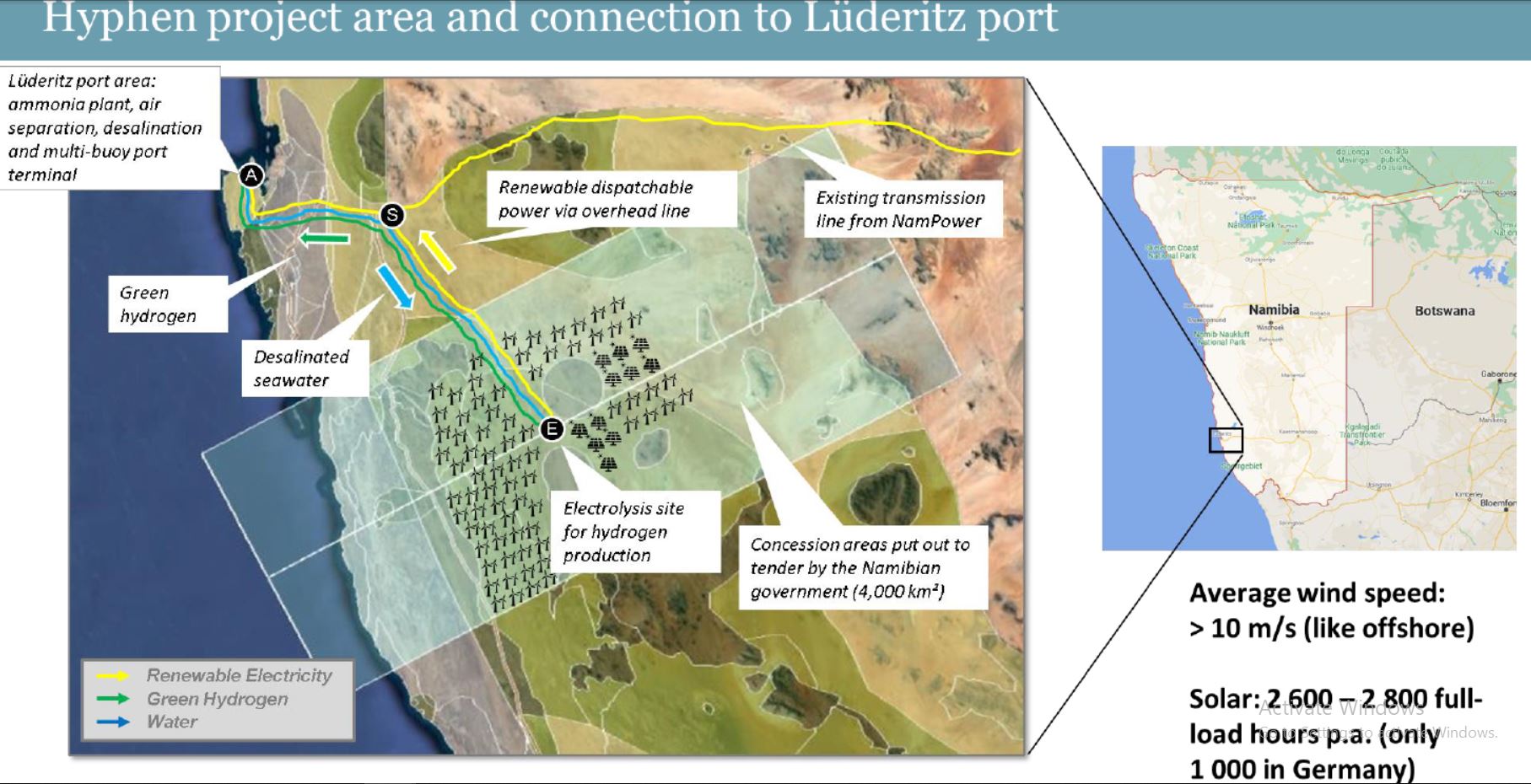

Government has committed to its partnership with Hyphen Hydrogen Energy to develop the first of the valleys and the Southern Corridor Development Initiative (SCDI), encompassing Lüderitz port and the tiny Aus settlement alongside two 2 000 km² land portions (Springbok and Dolphin) stretching from the waves into the desert. According to Jan-Barend (JB) Scheepers, the senior project developer, the average wind speeds are 10m per second, and solar radiation provides between 2,600 and 2,800 full-load hours per year.

Huge solar and wind farms will surround the electrolysis site (in Springbok) to power hydrogen production from desalinated water to be pumped from Lüderitz via Aus, while the excess renewable energy and the green hydrogen flow back towards the port.

Mnyupe described approximately 650 turbines standing at 160m high, equipped with sets of three blades, each around 80m in length. Scheepers elaborated on the commissioner’s preferred solution, which involves moving molecules instead of primarily moving electrons from the production site.

This involves a 1 400mm hydrogen pipeline designed to accommodate 3 Mtpa of ‘green’ hydrogen, in contrast to the need for forty-eight 400-kV overhead lines. Even with the pipeline, parallel electricity transmission lines will be needed to run downstream systems on renewable energy-generated electricity.

Battery storage will be integral to the Hyphen project infrastructure, connected with common user roads, water and hydrogen pipelines, and transmission lines to the Namib substation and the Nampower grid.

The expanded new Angra Point industrial site will house facilities for ammonia synthesis, air separation, ancillary site services, ammonia storage, water abstraction and desalination, and, through a multi-buoy mooring support, international shipping for refuelling and transporting renewable energy molecules abroad.

Schedules in place

Concerning timelines, Hyphen has already signed a feasibility and implementation agreement with the government in May. By 2024, the company intends to submit its comprehensive common-use infrastructure report, preceding the submission of the project feasibility report in 2025.

They aim to reach a final investment decision and financial close in early 2025, with the goal of bringing 1 million tonnes per annum of green ammonia production online by 2028.

Scheepers informed the masterclass that Hyphen is advancing with technical work streams, which include the SCDI master plan design. The company is in partnership with Namport, the Port of Rotterdam, and Invest International on the development of the Lüderitz port master plan.

Pre-feasibility studies have been completed, initial meteorological mast locations have been identified, revised technical dimension studies for wind and solar production are underway, and 10 masts and 2 LIDAR sites for remote earth surface sensing are being deployed, he said.

Hyphen’s own wind, solar, battery energy storage systems (BESS), electrolysis cooling system, ammonia loop, electrolysis, logistics and ammonia export facilities concept studies are underway, while early design work for common-use infrastructure has begun. An engineering capacity ramp-up includes recruitment and a project management database, as well as the appointment of an engineering partner, he added.

Green village takes shape

Progress at the first phase of the Daures Green Hydrogen Village is well underway, with construction in progress to initiate 'green' ammonium sulphate fertiliser production by 2024. The new village is located in the scorching heat of the Tsiseb Conservancy, near the foot of the Brandberg mountain range.

Jerome Namaseb, the young chief executive officer of the consortium and a founding member of Enersense Namibia, owns 90% of the ambitious development. The Daure Daman traditional authority holds a 7.5% stake in the project, while the Tsiseb conservancy holds 2.5%.

In partnership with the Scientific Service Centre for Climate Change and Adaptive Land Management in Southern Africa (SASSCAL) and facilitated by the relationship between the Namibian government and Germany, a donation of €12.1 million, approximately N$220 million, was secured from the German Ministry of Education and Research to fund the first phase of the giant development. This funding allows Namibia to take a significant step forward in the practical implementation of 'green' technologies essential for realising the global transition away from fossil fuels.

Well underway

Also in the race, and potentially the first to receive their 5MW electrolyser in December, is the partnership between the Ohlthaver & List group of companies and Belgium’s CMB.TECH. Their Cleanergy Solutions Namibia hydrogen production and refuelling plant is anticipated to be commissioned in 2024. According to O&L Group Innovation Director Eike Krafft, the electrolyser is just one component of the equipment required to produce hydrogen, all of which is expected to be in place by the middle of next year. Ground-breaking at the site on Farm 58 outside Walvis Bay took place in September.

To accommodate all these developments, Namport has significant plans. According to port engineer Elzevir Gelderbloem, the port already has the capacity to scale up and meet upcoming demands. At Walvis Bay, the North Port provides room for expansion and can presently handle 800 000 containers annually, with the current facilitation being 170 000 containers. Similarly, the non-containerised capacity is 20 MT per year, while the current handling is 8 MT. The two existing liquid bulk jetties can accommodate 10 MT per year but are currently handling only 1.5 MT. A new multipurpose terminal is in the planning stages for the North Port.

In Lüderitz, the expansions will involve enlarging the main quay wall at Robert Harbour from 200m to 300m between 2024 and 2025, with the first ammonia export berth at Angra Point set to be commissioned by 2028, Gelderbloem explained during the masterclass. The expansion of Robert Harbour is being expedited, while the longer-term Angra Point masterplan offers the potential to establish up to 18 MT per year of ammonia export capacity.